产品中心 / Product center

|

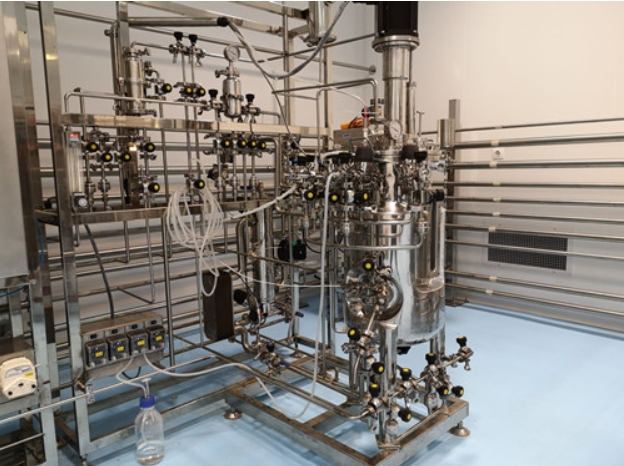

Automatic Bioreactor (5L-5000L)

Collect

Automatic Bioreactor (5L-5000L)

15L automatic fermenter BLBIO-15SJA-AUTO

30L automatic fermenter BLBIO-30SJA-AUTO

150L automatic fermenter BLBIO-150SJA-AUTO

300L automatic fermenter BLBIO-300SJA-AUTO

30L100L1000L2000L Automatic Fermenter(GMP)

500L1000L5000L Automatic Vaccine Fermenter BLBIO-500V-1000V-5000V 316L stainless steel tank, no dead angle of the tank, spherical tank bottom head, can obtain better fluid performance, the best mixing effect. The long glass sight glass is convenient for observing the state in the tank, and the special design of the mirror lamp is a quick interface, which is convenient and safe to operate. Standard pH, DO, and temperature interfaces are reserved, and aseptic sampling and discharge ports are designed with multi-valve combinations, and the top of the tank includes inoculation ports, feeding ports, foam electrode interfaces, exhaust condenser interfaces, and multiple backup ports. The pipeline valves are made of stainless steel, and the special sanitary pipeline valves for food and fermentation are simplified under the premise of realizing complete functions, reducing the chance of infection, and the structure is reasonable and beautiful. iameter-to-height ratio: 1:2~3; Liquid Charging Coefficient: 70% Sterilization method: automatic program sterilization Ventilation: automatic ventilation, thermal mass flow meter automatically controls the air flow Pressure: Pressure control range: 0-0.3Mpa, the pressure regulating valve automatically adjusts the outlet pressure, and the digital remote transmission display. Fermentation pH control function: intelligent PID control, METTLER PH electrode; Fermentation dissolved oxygen control function: intelligent PID control, METTLER DO electrode; Temperature control: intelligent PID control, electric heating, water cooling, circulating pump circulating temperature control, Feeding and defoaming: perfect feeding system (acid, alkali, bubble enemy, culture agent) BLBIO-UIP automatic lifting system of tank cover: lifting the tank cover through the electric system, easy to clean and maintain BLBIO-SIP tank automatic sterilization system: a patented product researched and developed on the basis of European fermentation tanks, one-key operation, reducing the labor intensity of the operator BLBIO-CIP tank automatic cleaning system (optional): cleaning the tank through the automatic system, reducing labor intensity BLBIO-C type control system: industrial control computer +Siemens S7-200 series PLC control system, it is a mature, stable and general-purpose PLC, which can be suitable for various applications of automation and suitable for the research of process control in the production and manufacturing process. With its modularity, easy-to-achieve distributed configuration and easy-to-master characteristics, Siemens PLC control core has become an economical and advanced control system for the implementation of biological reaction process control. The system uses a tablet computer of more than 10 inches to control 8 direct parameters such as pH, DO, tank pressure, temperature, speed, air flow, defoaming, feeding, etc., and three processes: automatic sterilization of tank pipeline, automatic cleaning of tank body, and automatic lifting of tank cover, and can calculate indirect parameters. pH and DO electrodes can be easily calibrated by software; Initial control state of set parameters BLBIO-8.0 analysis software is based on the theory of detection and control of cell and molecular biometabolic flux and has been rich in microbial fermentation process optimization research for many years. The functions of this software are mainly as follows: A: Accurately calculate indirect parameters such as OUR, CER, RQ, KLa and so on, and can display a number of curves with different parameters on the same coordinate plane at the same time; B: Accurately display the material balance and changes in the fermenter, which is convenient for users to analyze the correlation of the fermentation process, so as to help users derive appropriate control points and achieve the purpose of one-step scale-up of pilot test; C: It can input the detection data of total sugar, reducing sugar, amino nitrogen, bacterial concentration, fermentation unit and other offline and generate the corresponding curve under the online process parameter curve; D: It mainly has the following functions: multi-tank parallel sampling, multi-batch number data direct comparison, unified display and comprehensive analysis of multiple data, convenient self-customization ability (you can program it yourself), online data real-time sampling, online data real-time processing and displayManual parameter input, indirect parameter automatic calculation, data query and display of custom parameter graphics, report printing This equipment is a relatively high-end product developed by our company, suitable for large-scale pharmaceutical factories and research institutes to optimize the process Add optional features: b. Feeding balance weighing W Tank weighing D Automatic control of air flow e Tank pressure detection f Bypass pure oxygen g On-line detection of redox potential h On-line detection and control of methyl (ethyl) alcohol content I On-line detection of tail gas O2 and CO2 content A Automatic sterilization function C. Automatic tank cleaning function U Automatic lifting function of tank cover |