产品中心 / Product center

|

|

Glass Bioreactor (magnetic stirring)

Collect

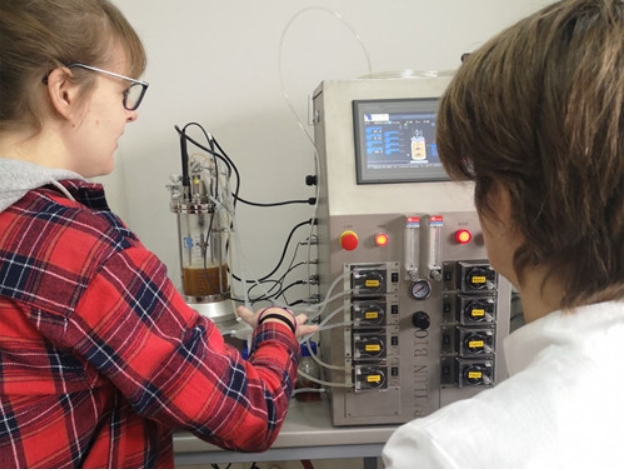

Glass Bioreactor (magnetic stirring)

0.2 liter displacement sterilization magnetic stirring glass fermentation tank BLBIO-0.2GC

0.5L out of place sterilization magnetic stirring glass fermentation tank BLBIO-0.5GC

2L out of place sterilization magnetic stirring glass fermentation tank BLBIO-2GC 5-liter displacement sterilization magnetic stirring glass fermentation tank BLBIO-5GC 20L Off site Sterilization Magnetic Stirred Glass Fermentation Tank (Desktop) BLBIO-20GC 0.2/0.5/0.7/1/2/3/5/7/10/15/20 liter displacement sterilization magnetic drive mechanical stirring glass fermentation tank Nominal volume: 0.2/0.5/0.7/1/2/3/5/7/10/15 liters Magnetic stirring: diameter to height ratio: 1:2-3; Liquid filling coefficient: 70% Tank body: The lid and bottom of the tank are made of 316L stainless steel, with a stainless steel cooling jacket for easy operation and cleaning; Stainless steel internal polishing accuracy Ra ≤ 0.4; The part in contact with the material is a 316L motor: an AC motor that can operate in harsh environments; Ventilation: The rotary flowmeter displays and adjusts the gas flow according to the process requirements. The stirring system adopts a strong magnetic mechanical suspension magnetic stirring system (fully sealed, zero leakage, pollution-free, changing the dynamic seal into a static seal, completely solving the problem of bacterial infection in biological product tanks); There is no top needle at the bottom, and the stirring speed is 0-1000rpm; Mixing form: straight blade stirring paddle (second stage), mechanical compression defoaming paddle (first stage), fermentation pH control function: using intelligent PID control, dedicated PH electrode; Fermentation dissolved oxygen control function: adopting intelligent PID control and dedicated DO electrode; Temperature control: Large area stainless steel jacket ensures sufficient heat exchange area, electric heating, water cooling, and has good heat exchange efficiency; Cooling water+5~65 ℃, ± 0.2 ℃, resolution 0.1 ℃. Supplementing: A complete replenishment system for sterilization: the sterilization pot is out of position for sterilization; BLBIO-B control system optional: The biological process controller is composed of a wellhead industrial control computer and I/O channels as the core, using a 10 "LCD display as the display interface, with rich and complete display content. The system has multiple related controls: speed and dissolved oxygen related control, feeding and dissolved oxygen related control, feeding and pH value related control, etc. The system has real-time display of the operating process, data and recording, data analysis (bar chart, curve chart and batch report), output printing, password management, abnormal analysis and other functions, with a Chinese interface. The recording screen can display multiple different curves at the same time, and if needed, more curves can be displayed at once. It can select any number of curves from different fermentation batches to be displayed simultaneously for comparative analysis; The parameters of each detection and control circuit can be manually set and corrected online on the screen, and temperature can be adjusted The setting and calibration of DO and PH sensors, calibration of the flow rate of each peristaltic pump, and password protection function for operation. Technical parameters: Mixing speed: Speed: 0~1000rpm, continuously variable; Accuracy: ± 1rpm; PH control: Display range: 0.00~14.0ph; ± 0.01ph, fully automatic control range: 2.00-12.00ph, control accuracy: ± 0.02ph, resolution: 0.01ph; DO control: can be associated with speed; Range: 0.1~150%, control accuracy: ± 3%; Resolution: 0.1%; Temperature control: range: cooling water temperature+5-65 ℃; Accuracy: ± 0.2 ℃; Resolution: 0.1 ℃; Foam control: electrode detection, peristaltic pump replenishing defoamer, automatic control; Ventilation: manual adjustment, flow meter display; Tank pressure: manual adjustment, pressure gauge display; Range: 0~0.20Map; Add optional features: b Supplementing balance weighing W tank weighing D automatic air flow control E tank pressure detection F bypass pure oxygen g Online detection of redox potential h Online detection and control of A (B) alcohol content in tail gas O2 CO2 content online detection A automatic sterilization function C automatic tank cleaning function Automatic lifting function of U can cover Model annotation: BLBIO XABC-D X - Total tank volume: A - Tank material: - G: glass/- S: stainless steel - C animal cell tank - V vaccine tank - M enzyme reactor B - Transmission mode: - C: Magnetic drive mechanical stirring/- J direct drive mechanical stirring/- Q airflow stirring - S solid stirring - L provides light source C -- Add optional functions - A Automatic sterilization - No manual sterilization - Y Glass in-situ manual sterilization - U Can lid automatic lifting D - Controller model - A is an industrial control computer+control module - None is a B-type controller, which is our company's standard controller - C is a 10 inch LCD touch screen+PLC - D is a 15 inch LCD touch screen+Siemens PLC+imported transmitter - S stainless steel control box |